AI‑Powered Forecasting to Slash Food Waste with Predictive Analytics

AI-Powered Forecasting: Reducing Food Waste with Predictive Analytics

Food waste is a pressing challenge—globally, nearly one-third of food produced goes unused, generating significant environmental harm and financial loss. In India’s fast-evolving F&B scene—restaurants, pubs, cafés, breweries, and ice‑cream parlours—the stakes are high. Efficient inventory and demand management shape profitability and sustainability.

Enter AI‑powered predictive analytics. By transforming raw data—sales history, weather patterns, holidays, customer trends—into actionable forecasts, AI optimizes stock decisions, streamlines menu planning, and curbs spoilage.

This blog explores how AI forecasting works, its real-world impact, implementation tips for Indian operators, and the future of smart, waste‑free food service. Whether you’re a bar owner or an F&B consultant, this guide clarifies how AI boosts both your bottom line and your eco‑credentials.

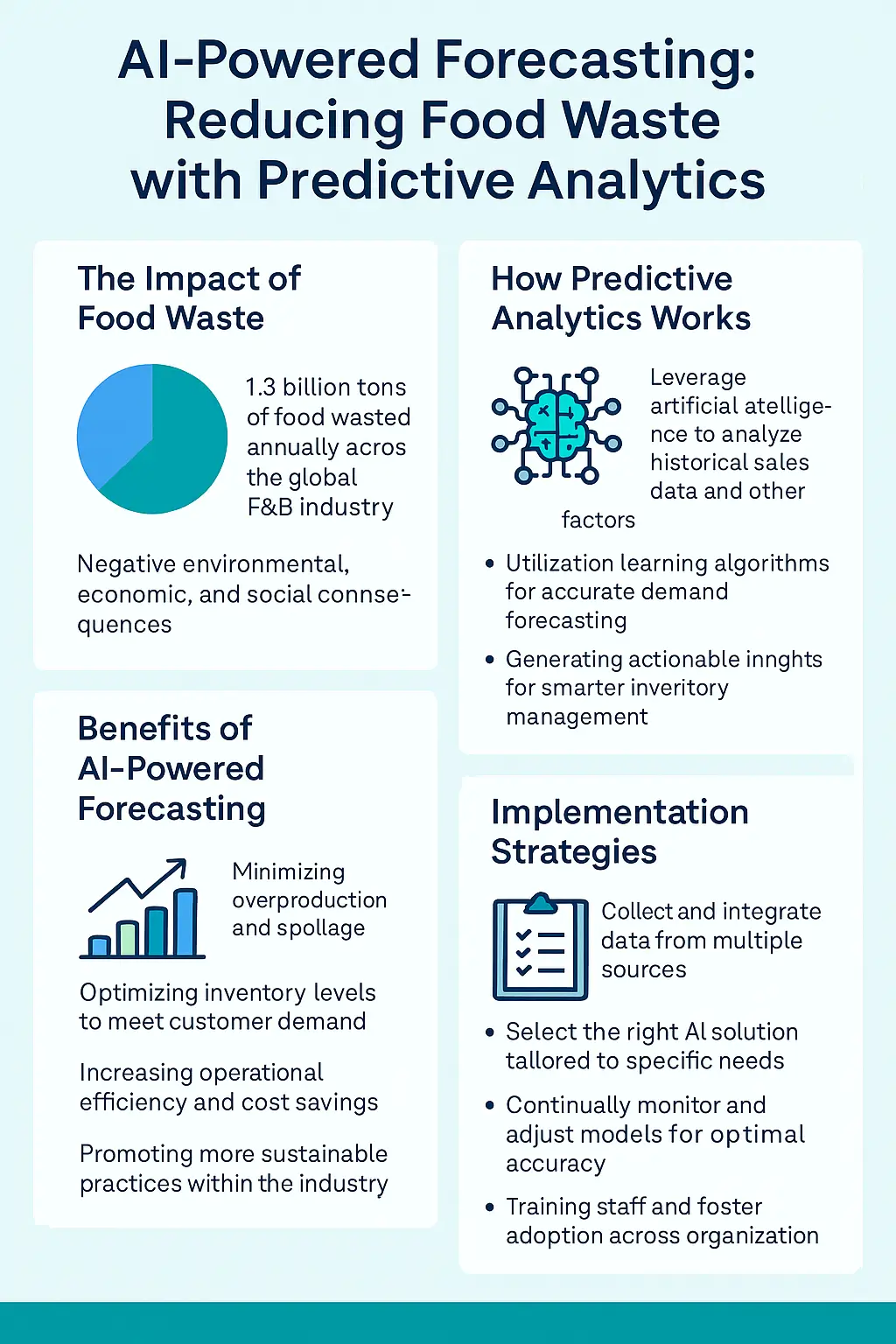

The Food Waste Crisis in F&B

- Scope of the problem: FAO estimates over 1.3 billion tonnes of food waste annually. This translates to lost revenue, landfill impact, water/waste, and methane emissions.

- Impact on Indian F&B businesses: Frequent overproduction—buffets, peak hours, festive surges—leads to both kitchen and plate waste. Manual forecasting and reliance on intuition result in stockouts or surplus, damaging profits.

- Why smart forecasting matters: Accurate demand forecasts cut overproduction and understocking, reducing cost and waste alike.

How AI Predictive Analytics Helps Curb Waste

- Demand Forecasting with ML models

AI leverages ML tools—time-series models, LSTMs, ARIMA, Prophet—and blends internal and external data (weather, festival calendars, trends) for dynamic demand predictions.

- Inventory Optimization

AI platforms track expiry dates, spoilage patterns, stock levels, and suggest reordering thresholds, minimizing waste from overflow and outdated inventory.

- Real-Time Waste Monitoring

Systems like Winnow use AI‑powered camera/scale tech to track waste in real time—Hilton saw a 76% reduction in kitchen waste and 55% drop in post-consumer waste in pilot sites.

- Menu and Portion Optimization

AI analyses leftover data and demand to recommend portion tweaks and rotate specials—driving profitability while reducing unsold items.

- Smart Routing & Redistribution

Emerging systems combine AI with IoT to detect surplus and route it to food banks or repurpose inventory—enhancing resource efficiency and supporting circular economy goals.

Indian Context & Emerging Practices

- Tech Adoption in India

Indian F&B providers are increasingly embracing AI. Startups offer AI-driven platforms for predictive inventory and spoilage management, aligned with FSSAI’s growing focus on food safety analytics.

- Local Innovation & Research

Precision tech for sorting even date fruits (e.g., SmartDate with Vis‑NIR sensors and RL) achieved >94% accuracy in quality control—minimizing waste.

Other academic initiatives involve ML-based price forecasting and cold storage solutions tailored for Indian farmers—empowering supply chain-to-retail efficiency.

- Challenges for Indian F&B Businesses

- Data scarcity—smaller cafés may lack historic data needed for accurate AI training.

- Infrastructure & cost—real-time sensors and premium software can strain budgets.

- Skill gap—understanding and integrating AI demands digital literacy.

Implementation Guide: Step-by-Step

Step 1: Define Objectives & Gather Data

Focus on high‑impact goals—e.g., reduce buffet leftovers or optimize weekend sales. Collect historical sales, spoilage logs, supplier lead times, festival schedule, and weather.

Step 2: Select AI Tools

- Forecasting: Cloud-based platforms or Excel‑integrated ML models.

- Waste tracking: Start simple—logging data manually before integrating AI tools like Winnow.

Step 3: Pilot & Calibrate

Run pilot during non‑peak, validate model accuracy (e.g., using R‑squared, RMSE). Tools like LSTM show R² of 0.9 in predicting app‑based restaurant orders.

Step 4: Train Staff

Upskill through workshops on interpreting AI dashboards, adjusting menus, and monitoring waste metrics.

Step 5: Scale & Communicate

Once success is proven, scale AI across locations. Publicize your green practices to customers—for brand value and marketing.

Step 6: Monitor KPIs

Track metrics: waste volume, cost per waste kg, spoilage rate, margin retention. Adjust system regularly to refine performance.

Benefits Overview

- Cost savings: Minimized spoilage and optimized ordering cut direct costs.

- Environmental gains: Less landfill waste, reduced carbon footprint, better resource utilization.

- Customer value: Fresher products, tailored menus, sustainability positioning.

- Operational agility: Demand-adaptive ordering, dynamic menus, lean operations.

- Compliance: Aligns with growing regulatory focus by FSSAI on food safety and traceability.

Overcoming Barriers

- Data maturity: Start with small pilots, refine data collection gradually.

- Budget constraints: Begin with low-cost solutions like Excel models or lightweight SaaS forecasting.

- Resistance to tech: Emphasize staff training, showcase quick ROI, promote team involvement.

- Vendor selection: Choose local startups or established tech providers with F&B and Indian market experience.

Future Outlook

- Integrated ecosystems: AI + blockchain + IoT for traceability, spoilage prevention, and trust-building.

- Smart kitchens: IoT sensors offering predictive spoilage alerts and automated reordering.

- Circular collaborations: Linking F&B outlets with local NGOs and farms to redistribute excess food.

- Consumer-level AI: Apps that suggest recipes based on inventory to reduce household waste.

Conclusion

AI-powered forecasting offers a transformative path for F&B operators in India—from pubs to parlours. By blending predictive analytics, waste monitoring, and smart data-driven decisions, businesses can significantly reduce waste, boost profitability, and elevate sustainability. While implementation needs careful planning and onboarding, the long-term payoff is compelling.

Embrace AI not just as technology, but as a strategic partner in reshaping food operations—today, tomorrow, and for a greener future.