Future-Proof Your Kitchen: How Automated Kitchens Could Shape India’s F&B Backend

Kitchen Automation: How to Future-Proof Restaurant Backends

Imagine you walk into your restaurant kitchen at 8 a.m. Instead of the chaos of pots clanging, onions being sacrificed to the floor, and a chef shouting “Who stole my ladle?!” — you’re greeted by a calm hum.

A robotic arm flips parathas with the grace of Hrithik Roshan dancing in Kaho Na Pyaar Hai. A screen flashes your daily forecast: 134 biryanis, 220 cappuccinos, 67 chilled beers, 45 chocolate sundaes. Meanwhile, your inventory management system has already placed an order for coriander because it knows Delhi’s weather forecast predicts rain — which means pakora demand will spike.

Sounds futuristic? Not anymore. Kitchen Automation is no longer just a Silicon Valley buzzword — it’s the spicy, sizzling, and slightly messy reality that’s reshaping how India eats, drinks, and runs restaurants.

Whether you’re running a café in Pune, a brewery in Bangalore, or a dosa joint in Chennai, one truth is clear: Automated kitchens are the future of restaurant business. And the future isn’t coming slowly — it’s arriving faster than your Zomato delivery guy on a bike.

Why Kitchen Automation, Why Now?

Running a restaurant in India today is a bit like juggling knives blindfolded while riding a unicycle. Let’s count the battles:

- Labour shortages: Finding reliable kitchen staff is harder than finding parking in Koramangala on a Saturday night.

- Rising ingredient costs: Tomatoes are suddenly more expensive than gold.

- Customer expectations: Thanks to Swiggy and Zomato, your customers expect food to arrive hot, perfect, and Instagram-worthy.

- Health and safety rules: Compliance is now stricter than your mother-in-law’s scrutiny of your wedding photos.

COVID was the giant shove nobody asked for. With delivery and cloud kitchens booming, the backend had to evolve. The pandemic taught us this: you can’t fight 21st-century problems with 20th-century kitchens.

And here’s the kicker — India’s cloud kitchen market is expected to hit $2.8 billion by 2030. But that growth won’t happen if your backend still runs on sticky notes, shouting matches, and Excel sheets nobody updates.

That’s where restaurant automation comes in: making kitchens smarter, faster, and more profitable.

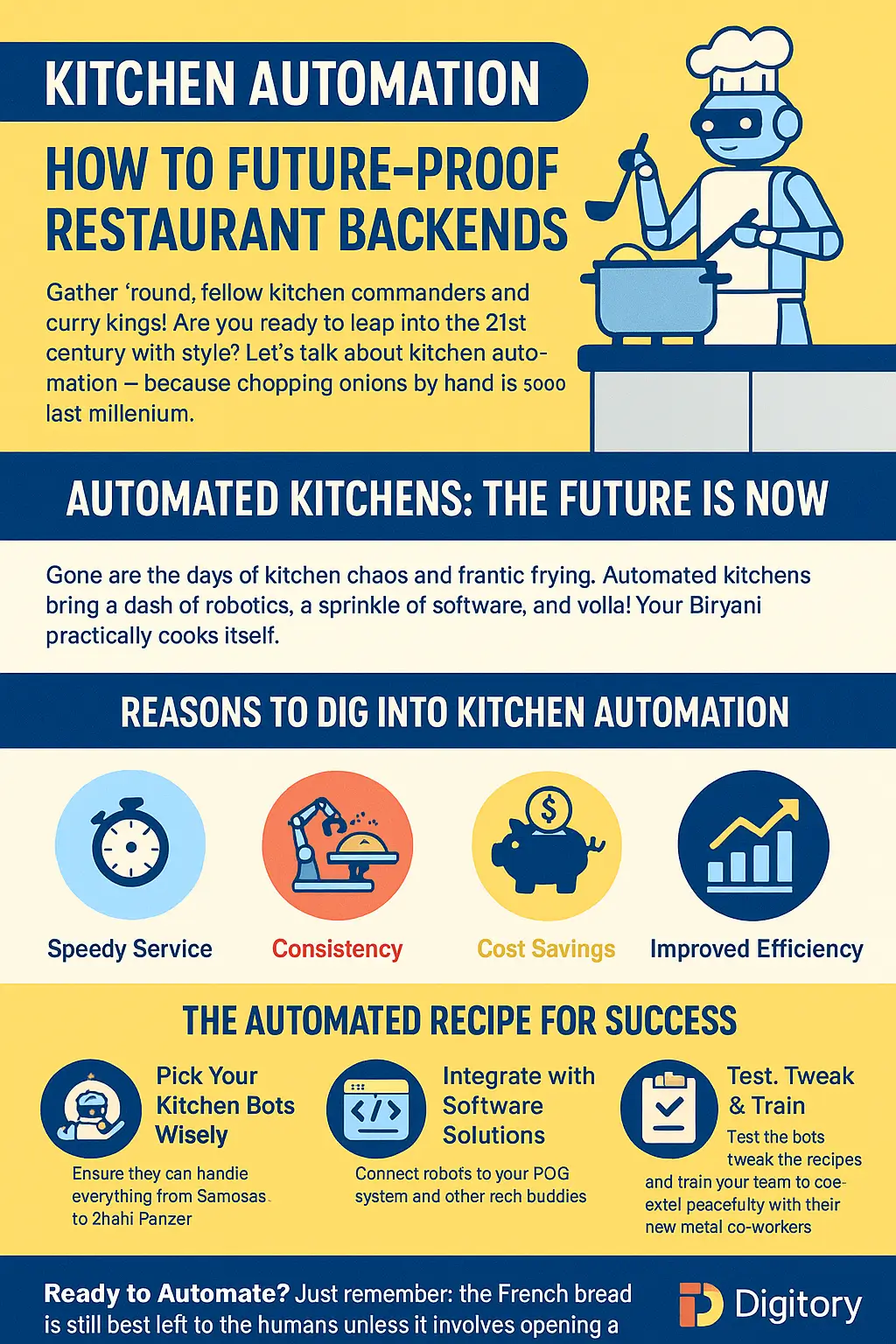

The Big Benefits of Kitchen Automation

So, why should an F&B owner invest? Let’s put it in masala chai terms: automation is the sugar that dissolves silently but changes the entire flavour.

- Speed & Efficiency

No more bottlenecks. Automated fryers, robotic arms, and pre-programmed recipes mean butter chicken isn’t waiting 30 minutes on the stove. Machines don’t get tired, they don’t need chai breaks, and they definitely don’t call in sick on IPL match days.

- Accuracy & Consistency

Every momo tastes the same. Every cappuccino has the same froth. No more “chef’s mood swings” influencing your customer reviews. In a country where one bad dosa can spark a 1-star Google rating war, consistency is survival.

- Cost Savings

Yes, the upfront cost makes some owners gulp harder than after drinking an extra-strong espresso. But think long-term: automation reduces wastage, lowers dependency on labour, and optimizes utilities. The result? Higher margins and faster scalability.

- Scalability

Want to expand from 1 café in Hyderabad to 10 across South India? Automation makes it easier. Central kitchens + POS integration + inventory automation = same taste, everywhere. No franchise headaches, no “this outlet tastes different” complaints.

- Data-Driven Decisions

Imagine your system whispering: “It’s exam season — stock up on Maggi and coffee.” Or “Rain forecast in Delhi — pakora demand incoming.” That’s the power of predictive analytics in automated kitchens.

- Sustainability

Controlled portion sizes, less waste, and energy-efficient appliances. Today’s diners love a restaurant that cares about the planet. And honestly, saving money while saving the Earth? That’s a win-win.

Tradition Meets Tech: The Balancing Act

Here’s the tricky bit: Indian food is messy, layered, and soulful. Teaching a robot to roll a perfectly round roti is like teaching a cat to fetch. Possible, but not without comedy.

How does a machine decide when a jalebi is golden-crisp but not burnt? Or when your butter chicken gravy has the right amount of tadka?

This is where automation and humans dance together. Robots handle repetitive, boring jobs: chopping onions, stirring curries, frying samosas. Chefs, meanwhile, become artists and innovators — creating new recipes, blending flavours, and ensuring the soul of Indian food stays alive.

Think of automation as your sous-chef, not your master chef. The heart of your kitchen still beats with human creativity — automation just keeps the blood flowing faster.

Case Studies: When Kitchens Went Digital

- The Pandemic Push

During COVID, pizza chains and QSRs in India adopted semi-automated kitchens — robot arms for flipping burgers, conveyor ovens, AI-driven inventory tracking. The result? Faster service, reduced staff dependency, and zero compromises on safety.

- APICbase

A European solution now popular globally, APICbase integrates POS with backend kitchens. It tracks recipes, inventory, and analytics in real-time. Imagine never hearing the phrase, “Oops, we ran out of paneer” again.

- Cloud Kitchens in India

Companies in Bangalore, Delhi, and Mumbai are experimenting with AI-driven demand forecasting. Example: one cloud kitchen saw a 20% reduction in wastage by aligning prep schedules with real-time delivery data.

- Breweries & Cafés

Automated brewing systems help microbreweries in Gurgaon and Bangalore maintain consistency — every pint of IPA tastes the same. In cafés, smart coffee machines whip up 200 cappuccinos a day with zero variation.

Overcoming Challenges & Fears

“Will robots take our jobs?”

Not quite. Automation changes roles instead of eliminating them. Instead of 10 cooks chopping onions, you’ll need:

- 2 automation supervisors

- 1 data analyst

- 1 chef innovating new recipes

New skills, new jobs — not fewer jobs.

“It’s too expensive!”

True, initial investment feels heavy. But phased adoption works:

- Start with POS + KDS (Kitchen Display Systems).

- Add smart ovens or fryers.

- Move to robotics later.

“But Indian food is too complex!”

Valid point. Making a thali is far more complex than flipping a burger. But hybrid kitchens (human + machine) are already solving this — machines handle repeatable tasks, chefs handle the art.

A Playbook for Indian F&B Owners

Here’s your spicy recipe for future-proofing your kitchen:

- Start Small

Automate billing, ordering, or simple prep tasks first. Don’t buy the entire robotic orchestra on day one. - Pick Your Pain Point

Is your biggest headache wastage? Go for automated inventory management. Slow order turnaround? Try kitchen automation systems linked to POS. - Train Your Team

Your staff should see machines as helpers, not enemies. Upskill them to supervise tech and focus on creative tasks. - Think Central

If you plan multiple outlets, invest in a central kitchen powered by automation. It ensures taste and consistency scale with your brand. - Measure ROI

Automation isn’t just cool — it must be profitable. Track savings, efficiency, waste reduction, and customer satisfaction.

The Future Is Cooking

Fast forward to 2030. You step into your Delhi café. A robot barista serves you a latte with froth art shaped like the Taj Mahal. Your inventory AI whispers that samosa sales are up 18% during monsoon. Your margins are healthier, your chefs are happier, and your customers are loyal.

Automation hasn’t stolen your kitchen’s soul. It has amplified it.

Because the truth is this: kitchen automation is not about robots replacing chefs — it’s about future-proofing your backend so your restaurant thrives in a world where speed, consistency, and data matter as much as taste.

Automation is not the enemy. It’s the secret ingredient.